Safety Drives Everything We Do

With a commitment to be the safest provider of natural gas services, the safety of Atmos Energy’s employees, customers, and communities has always been our number one priority. Safety is at the core of what we do. It's a value reflected in our Vision, essential to our culture, and evident in our people, processes, procedures, and practices.

Aligning with this vision, we have proactively adopted Pipeline Safety Management Systems (PSMS), which further reinforces and reflects our commitment to the safety of our personnel, the public, and the environment. PSMS is a comprehensive approach to managing safety, emphasizing continual assessment and improvement and proactively identifying and mitigating potential risks.

Operational Safety

Atmos Energy is responsible for operating over 79,000 miles of natural gas pipelines in more than 1,400 communities. There are many roles and responsibilities that contribute to operating safely, effectively, and reliably, and many factors that all Atmos Energy employees consider when performing their jobs. However, none are more important than safety.

Our commitment to safety is rooted in AtmoSpirit principles. Our focus on Employee Safety, System Safety, and Public Safety drives our procedures, practices, processes, training, oversight, and assurance activities.

Building on this strong foundation that has supported our vision for decades, API RP 1173 Pipeline Safety Management Systems (PSMS) was implemented organically at Atmos Energy. The 10 PSMS elements align with our AtmoSpirit principles and are integrated into our approach to risk management and pipeline safety to continuously improve practices that enhance the safety of employees, customers, and the communities that we serve.

Safety isn’t just what we do, it is who we are.

“It is a testament to the dedication and commitment of every employee that Atmos Energy is intensely focused on safety, which is reflected year-round as we live our AtmoSpirit principles in the communities we serve.”

John McDill, Senior Vice President of Utility Operations

Pipeline Safety

Pipelines are highly regulated by federal and state requirements. Over the years, the landscape of the natural gas industry has changed substantially, with new technologies, evolving customer needs, and increasingly stringent safety regulations. These changes advance natural gas’s safe transportation and delivery to customers and communities. Atmos Energy’s holistic approach to safety includes focusing on our system’s long-term safety and reliability. In fiscal year 2023, we directed approximately 85% of our capital spending toward the continued modernization of the safety and reliability of our distribution, transmission, and storage systems.

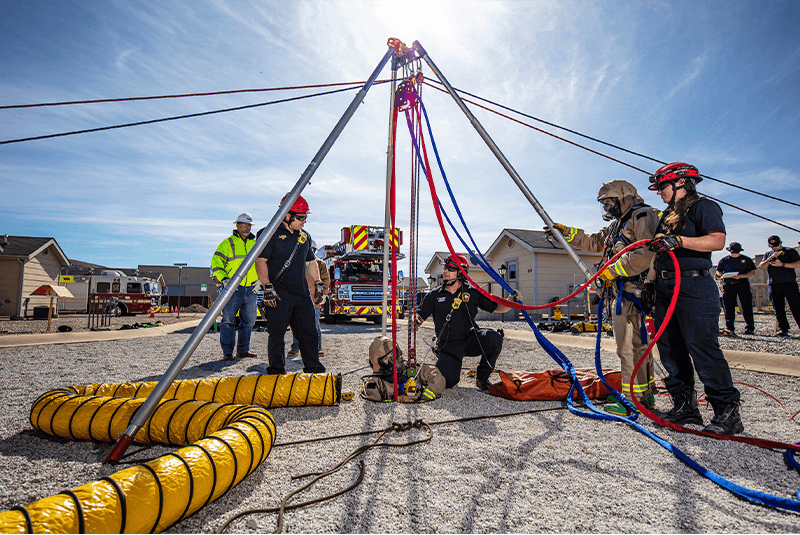

Training for Safe Operations

Atmos Energy field employees receive extensive in-person, virtual, and hands-on training and participate in our Pipeline Safety Management System which provides continuous feedback.

Atmos Energy field employees receive extensive in-person, virtual, and hands-on training and participate in our Pipeline Safety Management System which provides continuous feedback.

Through our robust safety and technical training programs, our employees acquire the skills to perform their work safely. We utilize experienced Field Mentors in our operating divisions to support the delivery of hands-on safety and technical training, using both virtual and in-person training sessions. In fiscal year 2023, employees across our enterprise spent more than 9,000 hours on safety training and attended over 96,000 safety huddles. Learn more about our training and Atmos Energy Essentials in the Employees section of this report.

“My team and I were returning from a service call on a really hot day last summer. We saw an elderly gentleman stumbling as he walked and seemed to be in distress. We used the skills from safety training we received at Atmos and determined he had symptoms of heat exhaustion. We rendered first aid that we had been taught and called an ambulance.”

Andrew Armijo, Crew Leader

Safety Metrics

To assist in measuring our successes and finding opportunities for improvement, we evaluate our safety performance using a variety of metrics. Our current Recordable Injury Rate (RIR) and Days Away/Restricted/Transfer Injury Rate (DART) have continued to decrease compared to 2017. In addition, our Reportable Motor Vehicle Collision Rate (RMVC) outperforms the American Gas Association (AGA) industry average for vehicular safety.

(per 200,000 hours worked)

(per 200,000 hours worked)

(per 1,000,000 miles driven)

AGA Peer Review Program

To reinforce our commitment to safety, Atmos Energy actively participates in the AGA’s voluntary Peer Review Program, which aims to support continuous improvement in safety and other important aspects of the natural gas industry. Each year, we collaborate with industry peers to discuss best practices and identify critical areas and opportunities for improvement. For more than a decade, Atmos Energy has joined other natural gas companies to pilot the Peer Review Program which has become the foundation for a nationwide industry effort to further advance safety.

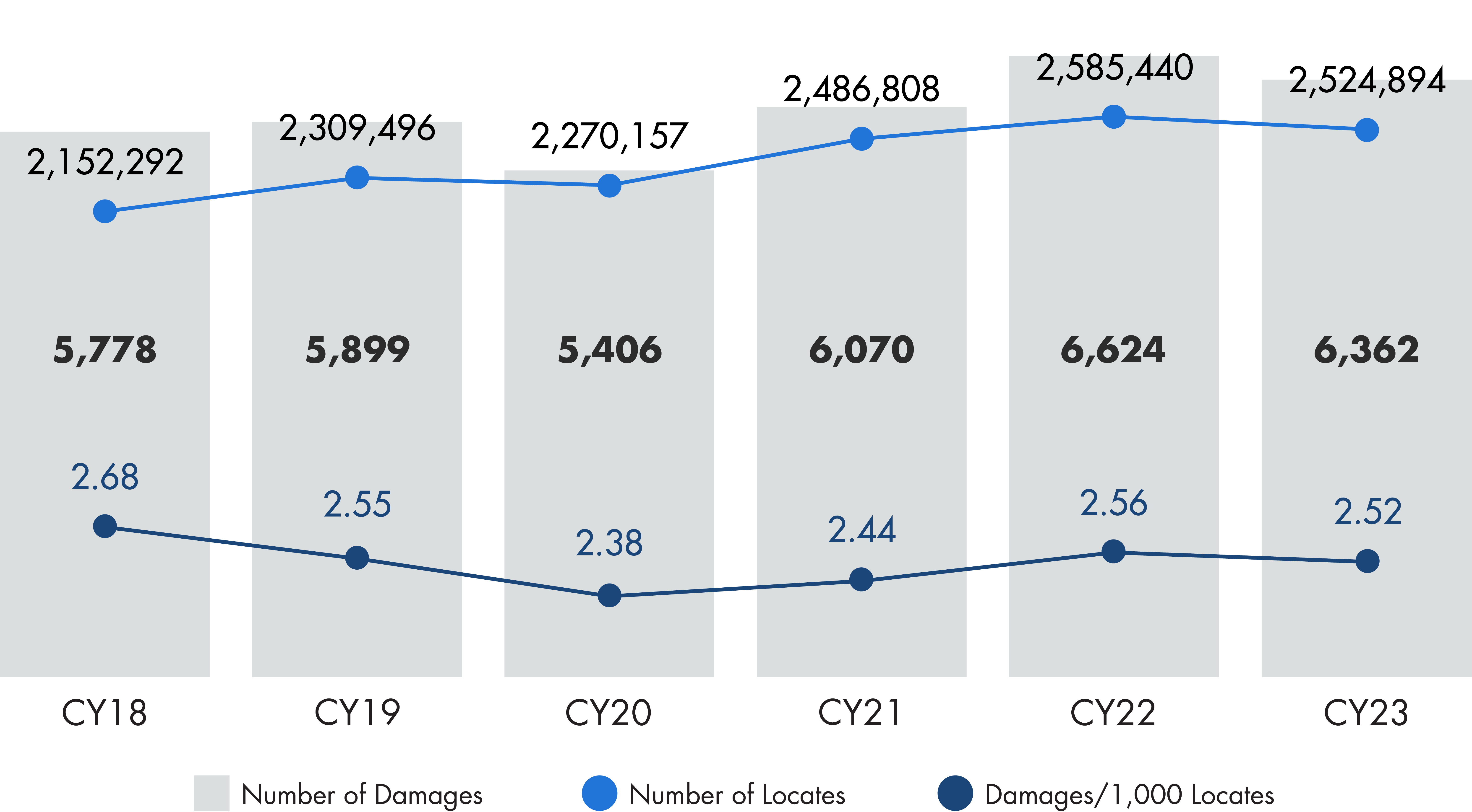

Reducing Third-Party Pipeline Damage

With increasing public infrastructure projects and expanding economic development, damage to our pipelines from excavation remains a primary safety risk. We promote safe digging practices by encouraging customers, contractors, and utility operators to call 811 before excavation. Opening an 811 ticket prompts utility members to locate and mark their facilities at a work site for safe excavation. We emphasize the importance of contacting 811 through community events, social media posts, and public relations activities.

With increasing public infrastructure projects and expanding economic development, damage to our pipelines from excavation remains a primary safety risk. We promote safe digging practices by encouraging customers, contractors, and utility operators to call 811 before excavation. Opening an 811 ticket prompts utility members to locate and mark their facilities at a work site for safe excavation. We emphasize the importance of contacting 811 through community events, social media posts, and public relations activities.

Our robust, multi-channel safety awareness strategy includes proactive public awareness campaigns, community events, media, and continued relationships with regulators, city leaders, and first responders. Additionally, we communicate natural gas safety information to our customers and the public through bill inserts, on-hold messaging, signage, and customer e-mails.

Atmos Energy’s Damage Prevention Ambassador program empowers employees to actively monitor our system and make stops at excavation sites to educate the public and promote safe digging practices, including contacting 811. If our Ambassadors find that the excavators have invalid or expired 811 tickets or their excavation plan includes the use of mechanized equipment within the utility tolerance zone without first exposing the utilities, they will ask the excavator to cease digging immediately. In these cases, digging will not resume until utilities have marked their lines, as required under state law. In calendar year 2023, our Ambassadors performed over 68,000 stops and distributed nearly 35,000 pieces of literature to excavators and homeowners. This is one more way we put our safety vision into action.

As the number of locate tickets across our service territories has remained steady due to strong economic development and population growth, our damage prevention awareness efforts have resulted in a decrease in the number of damages caused by third parties per locate ticket. Since calendar year 2018, our damage per thousand locate ticket rate has trended downward from 2.68 to 2.52 in calendar year 2023.

Public Safety, Emergency Preparedness, and Emergency Response

Atmos Energy partners with various regulators, local community groups, and first responders to advance pipeline safety awareness and emergency response efforts. We coordinate with local fire departments and other first responders to assist in emergency response during a natural gas leak. Our First Responder Natural Gas Workshops provide emergency response teams with detailed information and procedures to work around natural gas and carbon monoxide safely. Atmos Energy prepares and maintains local emergency plans for specific operating areas, and local supervisors conduct annual reviews of these plans. We also conduct tabletop exercises and emergency plan refresher training to confirm readiness and preparedness. During an emergency, our Incident Command System (ICS) provides guidance and instruction to Atmos Energy Emergency Responders, who follow the “H-E-L-P” action procedure—Determine Hazard, Extent of Hazard, Protect Life, and Protect Property. More information on our first responder partnerships can be found here.

Atmos Energy partners with various regulators, local community groups, and first responders to advance pipeline safety awareness and emergency response efforts. We coordinate with local fire departments and other first responders to assist in emergency response during a natural gas leak. Our First Responder Natural Gas Workshops provide emergency response teams with detailed information and procedures to work around natural gas and carbon monoxide safely. Atmos Energy prepares and maintains local emergency plans for specific operating areas, and local supervisors conduct annual reviews of these plans. We also conduct tabletop exercises and emergency plan refresher training to confirm readiness and preparedness. During an emergency, our Incident Command System (ICS) provides guidance and instruction to Atmos Energy Emergency Responders, who follow the “H-E-L-P” action procedure—Determine Hazard, Extent of Hazard, Protect Life, and Protect Property. More information on our first responder partnerships can be found here.

“I’ve worked at Atmos Energy for over four years, and to me, Atmos Energy represents the partnership to keep places we love and people we care for safe.”

Cole Fisher, Crew Leader